Rolls-Royce's small modular reactor

Could the UK company once famous for a luxury car now hold the keys to the SMR conundrum?

It’s only half over, but thus far 2025 is looking like a very good year for nuclear power.

Some sort of Nuclear Renaissance 2.0 is definitely going on.

Measured by terrawatts of electricity generated, nuclear world-wide had a record year in 2024, and is set to have another in 2025.

But there’re been nuclear renaissances before. The last one, circa 2007–2011, washed out with the tsunami at Fukushima.

But for Nuclear Renaissance 2.0, so far, so good.

On May 23, 2025, U.S. President Donald Trump issued four involved pro-nuclear executive orders.

Among other things, Trump directed the U.S. Department of Energy to get 10 nuclear reactors underway by 2030.

We’ll see how that goes.

The first half of 2025 also saw some satisfying mea culpas about nuclear power from unlikely places.

In June, New York state Governor Kathy Hochul came out in favor of building a new ‘advanced’ nuclear power plant in upstate New York.

“I’m embracing this,” Hochul said. “This is not your grandparents’ nuclear reactor.”

Hochul’s predecessor, Andrew Cuomo, infamously shuttered a non-advanced — but still perfectly good — nuclear plant at Indian Point outside Manhattan in 2021, building on the legacy of his father, Mario Cuomo, who in 1989 went to great lengths to prevent the opening of a perfectly good, and completed, $5.5 billion nuclear plant in East Shoreham on Long Island.

Last I checked, Sussex county residents and Long Island Lighting Company (LILCO) customers will finish paying that $5.5 billion off in 2026, having netted from the deal exactly zero in net-zero electricity.

Across the Atlantic, on June 9, Germany’s new chancellor, Friedrich Merz, said his country’s decision to shut down its nuclear plants was “a grave strategic mistake.”

One might say that. Merz said his new government will look into building small modular reactors (SMRs).

But 2025’s most interesting bit nuclear news, in my opinion, was a little-noticed item on June 10th, when a brand-new UK state entity, Great British Energy, announced that a subsidiary — official name ‘Great British Energy—Nuclear’ (GBE-N) — had selected the Rolls-Royce SMR as the winner of a two-year-long competition.

The U.S., with its Big Beautiful Bills, has no monopoly on the use of hyperbole in names for legislation, although the British are a bit more tongue-in-cheek about it. The ‘Great British Energy Act [of] 2025’ received royal assent on 15 May, 2025.

Among its other provisions, the Great Big British Bill pledged £2.5 billion to support small modular reactors generally.

Now, it should come as no little surprise that the home team, Rolls-Royce, beat out two foreign rivals, Westinghouse and GE-Hitachi, in the UK competition.

Although who owns Westinghouse at any given moment requires constant fact-checking, and a footnote.1

But economic nationalism aside, Rolls-Royce may actually have an excellent a shot at solving the SMR conundrum.

If anyone can.

It’s appropriate to be talking about the UK here, because in some way SMRs are a proposed solution to a problem uniquely created by Anglo-Saxon economics.

Countries where central planning is the norm have never had an ideological problem with state support for large nuclear.

China, according to the World Nuclear Association, has 32 reactors under construction.

Rosatom, Russia's state-owned nuclear energy corporation, is building 19 in 8 different countries, including not only China and Russia but also Turkey, Egypt, Hungary, Iran, India and Bangladesh.

At times, large nuclear has also done well in democracies with dirigiste tendencies, such as Japan, South Korea, and France.

But in the U.S. and the UK, building large nuclear has for decades been almost impossible, for a variety of self-inflected reasons.

The list of exceptions is short enough to prove the rule.

In the U.S., Vogtle Units 3 and 4, the first really new reactors there in 30 years, cost twice the initial estimate; put the reactor vendor, Westinghouse, into Chapter 11 bankruptcy; and took 15 years to finish, seven longer than planned. Vogtle 4 started putting electricity on the Georgia grid in April 2024.

Sizewell B was the last large reactor to go operational in the UK in 1995.

Sizewell C just won support in the 2025 budget round, 30 years later. It will have an estimated cost of £38 billion.

Hinkley Point C, under construction in Somerset, is infamously trapped in a Vogtle-like a spiral of cost overruns and delays.

With luck, Hinkley Point C will start putting electricity on the UK grid in 2031, with a final cost in the neighborhood of £47.9 billion, US$ 60 billion.

It’s not just nuclear. The Anglo-Saxon countries have shown themselves inept at building any sort large infrastructure in recent decades.

When, that is, they try to build it at all.

California’s high-speed rail project, approved by the state’s voters in 2008, has eaten through $23 billion in state and federal funding, but not laid a mile of actual track.

The UK’s high-speed rail project, HS2, is similarly bogged down. It may open after 2033. Or not.

I won’t mention the third runway at Heathrow. That idea has been around since the late 1940s, and, to quote, “could be operational” by 2035.

Fingers crossed!

A paradox behind the big, scary numbers for nuclear is: large reactors actually produces cheap electricity and are profitable investments, considered on the right timescale. The energy density of nuclear is that good.

Reactors can have 60, 80, or even 100-year lifespans.

Doing the math on the capital outlay on Vogtle Units 3 and 4 — $35 billion over 60-years at 90% capacity — works out to 3.31 US cents per kilowatt-hour.

To which we need to add something, say 1.5¢/kWh, for operation and maintenance (O&M), so make it 4.81¢/kWh.

For a point of reference, the lowest residential rate in the U.S. is 11.69¢/kWh, in North Dakota.

So plenty of of headroom there. The conventional wisdom is that a nuclear plant takes 25 years or so to return its invested capital.

I intentionally did not factor interest into that calculation.

Interest — whose mysteries are many — basically comes up when you attempt to compare competing investments.

A large nuclear reactor is infrastructure, not unlike a hydroelectric dam.

While it’s no excuse for project mismanagement, infrastructure can feel outrageously expensive in any era.

In 1933, then-new U.S. President Franklin Roosevelt suffered sticker-shock when the Bureau of Reclamation told him it would cost $168 million to build Grand Coulee Dam in Washington state.

In the decades since, in every cost-benefit analysis, Grand Coulee has returned that investment many times over with electricity and irrigation water.

Aside: The U.S. is blessed that greater generations bequeathed it its hydropower infrastructure. Consider about what it would be like trying to build it today, post-NEPA.

Like hydroelectric dams, large nuclear projects suffer from deep and painful capital draws.

In the Anglo-Saxon world, the scale of that capital draw creates a step-function.

The risk is that the business entity — say a private utility — simply gets knocked out of the game early.

In the long run, not much matters if you’re dead in the short run.

That explains why, in the U.S., the old fully-amortized nuclear plants are being snapped up by tech companies acting like frenzied shoppers at a yard sale.

But that low-hanging fruit is in limited supply.

Classic economics would say: build more large nuclear. Increase that supply.

But how?

Which returns us to the conundrum.

The SMR idea is: if you’re incapable of going large, go smaller.

There’s plenty of precedent for this in other industries.

Economy of scale has its limits.

The double-deck, 525-passenger Airbus A380 once seemed the future of commercial aviation.

Fortunately, it wasn’t. Medium-size planes proved to be a much better bet.

The SMR project, properly understood, is not about building one or two small reactors.

It’s about trying to build an industry.

Or, more, precisely an entirely new segment of an existing industry.

It’s going to be a long game, and will take staying power.

Bu the upside, potentially, is enormous.

Not one or two small reactors, but dozens. Perhaps 100s during the 2030s.

Nuclear is an international market.

Large nuclear is out of reach for much of the world. Not everyone can — or wants — to finance a $35 billion megaproject.

Thus any country that can pull off SMRs will get a valuable export industry.

As Russia has now, and the U.S. had with large nuclear until the 1970s. The Czech Republic, for example, has put itself on the list for Rolls-Royce SMRs.

Yet the SMR discussion is slightly odd and academic at the moment.

It doesn’t help that ‘SMR’ has become a political buzzword, encrusted with much magical thinking.

Some nuclear pundits, such as Mark Nelson, say the term SMR has become meaningless.

If we want to talk about small reactors, Nelson said recently, just talk about small reactors.

I think it’s worth trying to recover the original meaning.

A ‘small’ reactor is officially defined as one whose electricity output is under 300 megawatts (MW).

Although that number is a bit arbitrary. Rolls-Royce’s design in on ‘large’ side of small, at 470 megawatts.

That said, there are no SMRs—of any size—currently operating in the West.

Russia has two small (35 MW) KLT-40S reactors onboard its floating nuclear power ship Akademik Lomonosov, which has been operational since May 2020.

China has a 210 MW experimental high-temperature gas-cooled pebble-bed reactor that it connected to its grid in December 2021.

It gets worse attempting to define ‘modular’.

Every reactor — including the large AP-1000s built by Westinghouse at Vogtle — is touted by its manufacturers as having ‘modules’ of some description.

Modularity a long been thought to be a virtue in the construction business.

So everybody wants to have it, or at least be able to say they have it.

Each floor of the Empire State Building was designed to replicate the essentials of the floor beneath it, as well discussed by Bent Flyvbjerg and Dan Gardner in their 2023 book, How Big Things Get Done.

That allowed the Empire State Building to go up in just 18 months. It officially opened on May 1, 1931. The start of construction was January 22, 1930.

The idea that a nuclear power plant could be made modular was, best I can tell, first put forward in 1984 by an industry analyst named Joe Egan.

Egan outlined a vision of small factory-built prefabricated reactors that could, in his words, be “floated across oceans, up rivers, or be carted cross-country to operating sites.”2

So a metric for modularity might be what percent of the final plant is built in a factory, rather than at the construction site.

Some assembly required, as they warn. So simply building modules elsewhere is not the clearest-cut of definitions.

A tighter definition is: the factory-built modules have to be ‘road transportable’.

That means they have to be small enough to be hauled to the construction site by what the British call a lorry.

There are a few — literally — large problems with that.

In the Rolls-Royce design, the reactor vessel is 8 meters tall and 4 meters in diameter. Each of the 3 steam generators weighs 220 tons. They are 15 meters tall.

The NuScale VOYGR was one of the earliest SMR designs. Notice how the artist envisioned it getting around:

There’s further definitional confusion if we start talking about ‘advanced’ reactors and SMRs.

An SMR need not have an ‘advanced’ reactor core design. That’s one using, say, liquid sodium as a coolant or TRISO pebbles as fuel.

Aside: I like to put ‘advanced’ in quotes because nearly all of today’s advanced reactor designs are actually rather old. A long list of civilian nuclear reactor designs was dreamed up by something called the New Piles Committee at Los Alamos in 1944. The few designs they missed were largely on paper by 1950. That explains why contemporary ‘advanced’ nuclear has such a back-to-the-future feel about it.

Rolls-Royce’s choice of a pressurized water reactor (PWR) was, in the words of one Rolls-Royce engineer, “intentionally boring.”

No doubt to the disappointment of some nuclear engineering aficionados.

At least 50 ‘advanced’ reactor designs currently exist on PowerPoint.

And, to listen to the aficionados, their particular favorite — what with its radically simplified design and all — will make small modular a trivial business.

I hope they turn out to be right about that.

In the meantime, I think we have to respect Rolls-Royce’s decision to dance with the reactor it came in with.

Rolls-Royce has been building small PWRs for Royal Navy submarines since the late 1950s.

In one of those genealogical ironies that abound in the history of technology, Rolls-Royce’s submarine reactor — now very much its own after multiple generations of improvement — descends from a Westinghouse design provided to Britain under a 1958 US-UK Mutual Defence Agreement.

Rolls-Royce is not alone in its thinking that the well-understood PWR, with a 70-year history, is a good bet to make modular.

New Jersey-based Holtec International, one of Rolls-Royce’s early competitors the UK SMR competition, has the same idea.

The PWR is so well-understood that nuclear provocateur Bret Kugelmass, for years host of the Titans of Nuclear interview podcast, put open source blueprints for a 100 MW PWR on the internet in 2020.

Kugelmass’s idea is that poor countries that desperately need electricity, such as Nigeria, should just DIY their own small PWRs.

Aside: There’s no how-to video on YouTube yet, but you can watch a hand-waving sort of one here.

The challenge of making a PWR modular has less to do with nuclear engineering than the mechanical kind.

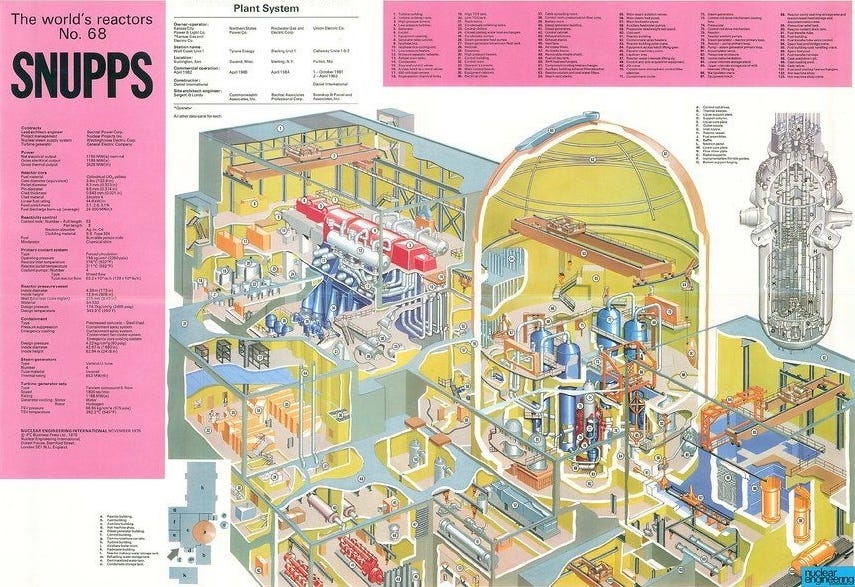

To visualize the problem, think about IKEA being asked to put this out in kit form:

Rolls-Royce appears to be taking modularity seriously.

It’s trying to break down everything possible so it can (a) be made at the factory (b) shipped in standardized modules and ( c ) put together, LEGO-like, at the construction site.

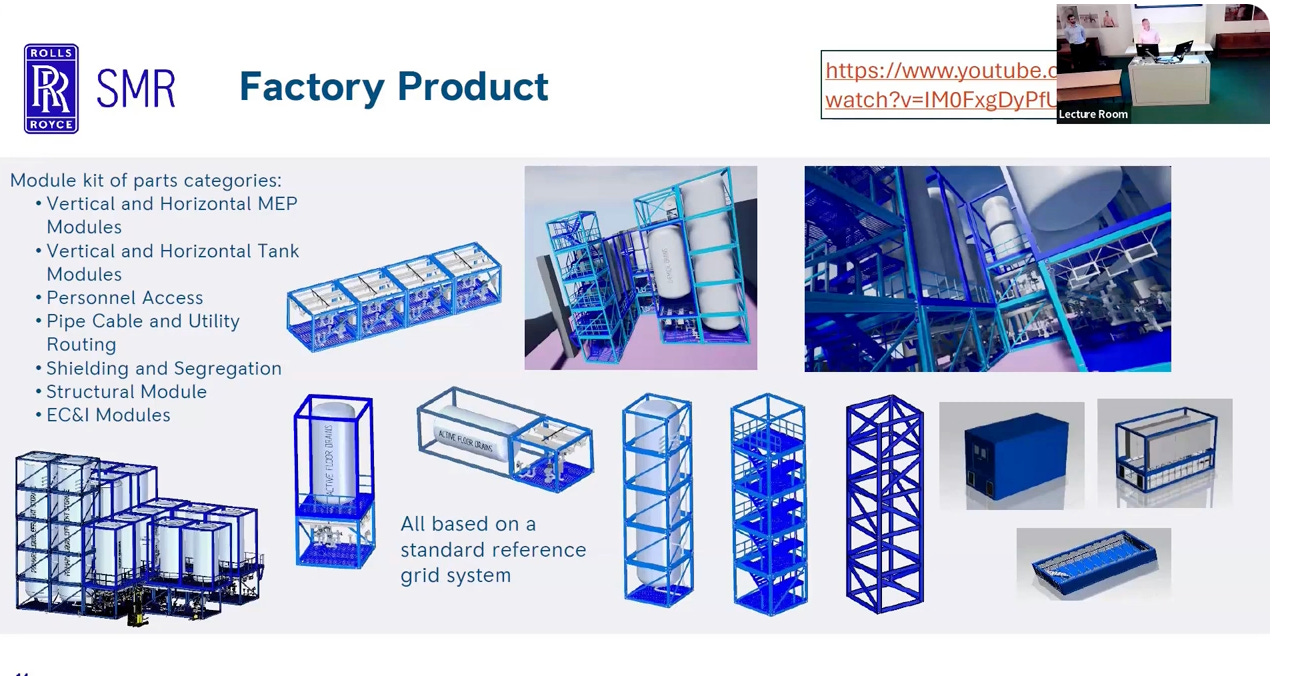

At one point, Rolls-Royce mentioned 1,500 transportable modules. Here’s some idea of what they look like:

It can’t be easy. The pipe exiting module #375 needs to line up with the intake valve on module #436. The modules have to be designed so workmen can crawl inside them. Any shipping crates that become a permanent part of the site may need to allow access for repairmen.

Rolls-Royce is working on building the module factory first, a promising sign of its sincerity.

The prototype factory is at the University of Sheffield's Advanced Manufacturing Research Centre (AMRC).

But part of Rolls-Royce’s deal with the UK government is that SMR production, if it happens, will someday reinvigorate former industrial centers.

So the actual factory or factories will be elsewhere, quite likely in the UK’s formerly industrial North. The current shortlist has six candidates.

A goal of the SMR project is not just to reduce cost by manufacturing everything possible in a factory, but to accelerate build time.

Rolls-Royce has some interesting ideas on that, too.

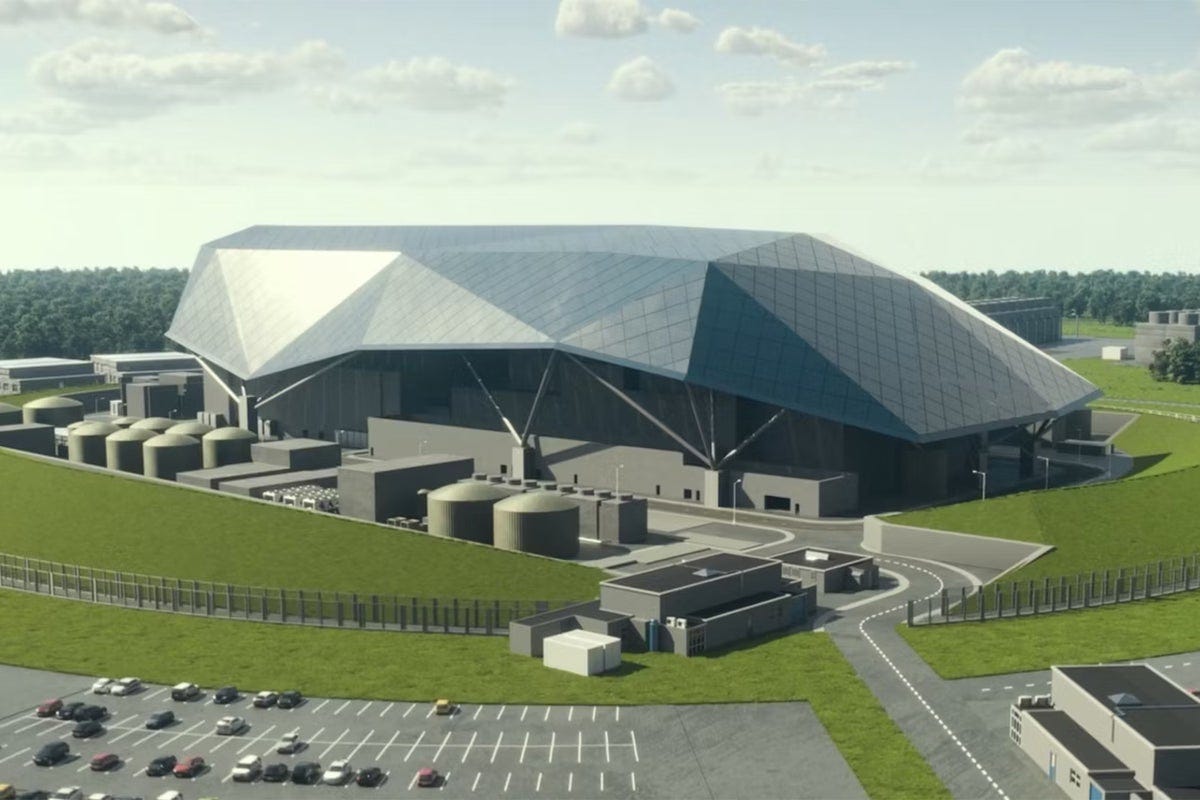

Because the SMR construction site will be relatively small — about the size of two football stadiums end-to-end, 100,000 m² — Rolls-Royce plans to put the entire thing under a temporary work shed.

The temporary building will also be put together, of course, with modules. When construction is done, the shed modules will move on to the next site.

In theory, the temporary building will allow construction to go on winter or summer, rain or shine.

Important if — as is widely tipped — the first Rolls-Royce SMR site is Wylfa in northwestern Wales, a location more known for rain than shine.

Rolls-Royce desperately wants to rule out any ‘bespoke’ changes for its SMRs.

This has to dovetail — or not — with how the UK does nuclear regulation.

At the national level, the UK has an Office of Nuclear Regulation (ONR) comparable to the U.S. Nuclear Regulatory Commission.

Aside: And subject of comparable criticism. See, for example, Katheryn Porter’s Watt-Logic blog on July 20, 2025 [Link].

The ONR allows reactor makers to apply for what’s called a Generic Design Assessment (GDA) which, if granted, means that a design is approved in general.

Three large reactor designs — the Westinghouse AP-1000, the AREVA/EDF EPR, and the GE-Hitachi ESBWR — currently have approved GDAs.

Rolls-Royce applied for its GDA in April 2022. The process usually takes about 4 years.

I think it’s safe to assume Rolls-Royce will get its GDA, although some enhancements Rolls wants to make to its PWR may make for minor speed bumps.

Rolls-Royce very much wants its reactors to have a 60-year design life, so it has changed the conventional PWR water chemistry to reduce corrosion.

But in the UK, building a reactor with a GDA still requires specific site approvals, primarily from local environmental authorities.

Roll-Royce’s plan is that the same SMR will be dropped on every site.

Thus any customization that might be required at some site — say, for seismicity —goes into the category of site preparation.

Aside: ‘Aseismic foundation systems’ — basically two rafts on rollers — have some history in earthquake-prone locations. Which the UK is not, the largest one recorded there in 1931 having put cracks in a few church steeples.

Local authorities in the UK have shown themselves to be highly capable — if they so desire — of setting up environmental roadblocks for infrastructure projects.

And the Roll-Royce SMR will need cooling towers, or cooling water.

If push comes to shove, Rolls-Royce may have to play its ‘defense national champion’ card for extra muscle.

That sort of idea is gaining traction in both the U.S. and UK. Earlier this year, a Tory peer introduced a bill in the House of Lords that would exempt nuclear power plant sites from regulation under the UK’s Conservation of Habitats and Species law of 2017, specifically preventing local authorities filing law suits.

Fortunately for Rolls-Royce, a legacy of the Cold War may make sailing smoother for in early days.

The UK already has a number of sites effectively pre-cleared for nuclear, those once occupied by its old ‘Magnox’ reactors.

The graphite-moderated and CO₂-cooled Magnox, an indigenous British design of the 1950s, was originally used for plutonium production.

Later, the Magnoxes proved to be reliable workhorses for electricity generation.

Wylfa, in northwestern Wales, a leading contender for a Rolls-Royce SMR, had two Magnox reactors that ran for 44 years, from 1971 to 2015.

Oldbury, near the tip of the Bristol Channel, is another Magnox site on the short list.

The aspirational target build time for the Rolls-Royce SMR is four years.

The first one will undoubtedly take longer.

My guess, as of this writing, is that if all goes smoothly we might see a Rolls-Royce SMR in operation at Wylfa in 2031.

That may seem far away, but a build time of five years would be a noteworthy engineering achievement in the West.

The argument that ‘nuclear takes too long’ is often heard from the renewables lobby.

That argument has been around a long time. In February 2010, Nick Cleg, then the leader of the Lib-Dem party in the UK, said :

By the most optimistic scenarios from the government itself, there’s no way they are going to have new nuclear come on stream until 2021, 2022. So it’s just not even an answer.

In the U.S., delaying nuclear projects has been a favorite weapon of anti-nuclear groups since 1971.

That’s when the Natural Resources Defense Council was allowed to sue the U.S. Atomic Energy Commission (AEC) on the claim that Maryland blue crabs might suffer if they got too close to the cooling water outlets of the Calvert Cliffs nuclear plant.3

Aside: Calvert Cliffs eventually got built. Fishing spots near the cooling water outlets are now prized by local anglers.

To quote a break-room poster: “The best time to plant a tree was twenty years ago. The second best time is now.”

An anticipated benefit of the SMR project is that once the factory starts churning out modules, multiple sites could be underway at the same time.

The true test, for both Rolls-Royce and the UK government, will come with the third.

If the SMR project works out, the question of how long the first one costs, and how long it takes to build, is slightly is off the mark.

That said, an old 2019 figure, no doubt now too low, for a Rolls-Royce PWR was £1.8 billion, US$ 2.3 billion.

On one schedule, Rolls-Royce projected the cost of the third will be 25% less than that of first, and the cost of the tenth 40% below the first.

Unfortunately, in their short — practically pre-natal — history SMRs have yet demonstrate immunity to the cost overrun diseases that afflict their larger brethren.

To be fair, SMRs start off handicapped in comparison to large nuclear. Their smaller output means the $/kW ratio has a smaller denominator.

In November 2023, NuScale’s ‘Carbon Free Power Project’ in Utah aborted when its cost-per-kilowatt estimate soared into Vogtle territory.

Earlier thus year, GE-Hitachi gave both Ontario Power Generation (OPG) and the Tennessee Valley Authority (TVA) estimates on the BWRX reactors each are planning.

OPG’s estimate, for 300 MW, converts to US$ 4.5 billion. TVA’s estimate is buried in the fine print of its integrated resource plan, but also seems to be around $5 billion.

On the subject of economic nationalism, Canada has an indigenous large reactor technology, the CANDU. That $4.5 billion has some Canadians wondering why Ontario Power should bankrolling GE-Hitachi’s SMR.

What could go wrong with Rolls-Royce’s SMR project?

I see two potential issues.

The first involves the staying power of Rolls-Royce SMR — the company — and, related, the staying power of the UK government.

The UK state has been deeply intertwined in Rolls-Royce’s history.

The original partnership between Henry Royce, engineer, and Charles Rolls, car salesman, dates back to 1906. That was Rolls-Royce Limited.

Royce and Rolls’ luxury cars quickly developed a sterling cachet. They were excellently engineered, yet also hand-crafted.

During World War I, the Air Ministry asked Rolls-Royce to try its hand at building engines for airplanes.

The first of many Rolls-Royce piston engines — all named after birds of prey — was the Eagle.

Two Eagles took John Alcock and Arthur Brown on the first non-stop flight across the Atlantic in 1919.

The Merlin, Rolls-Royce’s most famous piston engine, powered such planes as the Spitfire, Avro Lancaster, and P-51 Mustang during World War II.

‘Merlin’ comes from the name of the small dark falcon, not King Arthur’s court magician.

Rolls-Royce is currently the second-largest maker of jet aircraft engines.

Its entry into that business traces to a different wartime intervention by the British government.

Frank Whittle had a prototype jet engine working in 1937.

But after the start of World War II, Whittle’s little company, Power Jets Ltd., proved incapable of advancing jet engines fast enough to satisfy a frustrated British Air Ministry. It eventually handed the Whittle and his engine over to Rolls-Royce.

In 1971, after various technical and business missteps in the development of the RB211 engine for the Lockheed L-1011 TriStar, Rolls-Royce Limited went into liquidation.

At that point, the assets and ongoing business were acquired by the UK government and put into a new state-owned company, Rolls-Royce (1971) Limited.

In 1987, the Thatcher government sold off Rolls-Royce in an oversubscribed public stock offering. The current business entity is Rolls-Royce Holdings plc, traded on the London exchange as RR.

Along the way, the car business was sold off. Long story short, the Phantom continues to be made by a BMW subsidiary in Goodwood, West Sussex.

Rolls-Royce SMR was created as a separate company in October 2021, with about 150 engineers going over to it from the Rolls-Royce submarine reactor division.

As to Rolls-Royce SMR’s ownership:

76% is owned by Rolls-Royce Holdings.

11% is owned by BNF Resources UK Ltd, a London-based investment office of the family of French oil and gas billionaire François Perrodo.

10% is owned by the Quatar Investment Authority.

Baltimore-based Constellation Energy, formerly Exelon, has a 3% ownership share. Constellation, not coincidentally, operates some 20 nuclear reactors in the United States. Microsoft’s deal to restart the undamaged reactor at Three Mile Island is with Constellation.

Prior to the Great British Energy announcement in June, Rolls-Royce SMR had apparently gone through most of its initial round of funding, about £500.

As defense contractors know how to do, Rolls-Royce SMR will probably need to rely on repeat trips to the government well.

Nuclear at the moment enjoys the support of all three major British political parties — Labour, Conservative, and Reform — but the long-term budgetary staying power of the UK government cannot be treated as a given.

It was intended as joke, but in 2010 Labour’s outgoing Chief Secretary to the Treasury, Liam Byrne, left a note for his successor, “I’m afraid there is no money.”

The second potential danger for the SMR project is competitio.

Not from batteries or wind turbines, but large nuclear.

If — a large ‘if’ — large nuclear can put its house in order to take advantage of today’s pro-nuclear sentiment.

Two year ago, I speculated toward the end of in post about “The Lessons of Vogtle” that contrary to all logic, it might be an opportune time for someone to commit to building another AP-1000, even in the U.S.

The kinks had been shaken out. The supply chain had been built.

On July 16, 2025, Westinghouse CEO Dan Sumner made clear to Donald Trump that Westinghouse has ten AP-1000s to sell him, if Trump wants to buy them.

A test of whether large nuclear is back in the U.S. may come this year if someone decides to complete the V.C. Summer project in South Carolina, a Vogtle-twin AP-1000 build abandoned in 2017.

The AP-1000 would not be the only apex predicator in a revamped ecosystem where streams of money are flowing into large nuclear again.

Westinghouse and South Korea’s KEPCO have finally resolved a years-long legal dispute that might now make the KEPCO APR-1400 a formidable competitor. China could get aggressive about exporting its version, the CAP1400, developed by the State Power Investment Corporation.

The success of SMRs in that ecosystem will depend on how well Rolls-Royce can execute.

The hoped-for benefits of SMRs will have to materialize.

Now, it won’t be an qualified disaster if SMRs don’t turn out to be the answer to all the nuclear industry’s woes.

We’ll have some small reactors, some built more modularly than others.

For a brief shining moment in the 1960s, nuclear did follow the classic ‘infant industry’ learning curve of new technologies.

That ended in 1967, when the regulatory regime we associate with the 1970s started to kick in.

Since then — as well argued by Matt Ridley in How Innovation Works — nuclear has been exceptional for having a ‘negative’ learning curve.

Aside: Being on a negative learning curve is polite way of saying getting stupid.

“The story of nuclear power,” Ridley wrote in 2020, “is a cautionary tale of how innovation falters and even goes backwards if it cannot evolve.”

Nuclear stalled, Ridley wrote, “not for lack of ideas, but for a very different reason: lack of opportunity to experiment.”

The plethora of companies working on advanced nuclear may, at long last, create the trial-and-error ecosystem nuclear has needed to move forward.

But the Rolls-Royce SMR is also an experiment, and a well-thought out one at that.

Experiments don’t always work.

But Rolls-Royce should get its shot.

Westinghouse’s nuclear division, was for 7 years, 1999-2006, owned by British Nuclear Fuels Limited (BNFL), an entity that in 2024 got rolled up into Great British Nuclear. The Westinghouse that came out of Chapter 11 in 2017 is now 51% owned by a Canadian hedge fund, Brookfield Renewable Partners, and 49% by Cameco, a Canadian nuclear fuel and services provider. Westinghouse’s corporate offices are, as ever, located in Butler County, Pennsylvania, outside Pittsburg. The ownership of GE-Hitachi Nuclear Energy (GEH) is more straightforward: GE 60%, Hitachi 40% — although the GE bit has been restructured and is now part of a publicly-traded entity, GE Vernova Corp.

Egan, Joseph R., 1984. “Small reactors and the ‘second nuclear era’,” Energy, Elsevier, vol. 9(9), pages 865-874. Link.

The case is Calvert Cliffs Coordinating Committee v. AEC, 449 F.2d 1109 (1971).